Founded 180 years ago by Raphael Lock, the Ertingen-based company has been managed by Frank Lock, the 5th generation of the family, since 2002. The robust, self-locking, high-quality manual and electric drives and controls are the first choice worldwide for gardening and stable construction applications. Lock is also increasingly conquering industrial sectors with its product portfolio - particularly with solutions for lifting and adjusting tasks. In addition to independent dealers, the company's global network includes its own branches in the Netherlands, the USA and China. This enables Lock to offer expert advice, an extensive stock and fast on-site service.

Professional buildings for animals or plants have the highest demands on technical components for ventilation and other applications. Digital solutions ensure sustainable, efficient management. That is why Lock experts have been working on drive solutions, optimal building climate, environmental management and smart farming for years. With its innovative strength, Lock proves that drives, ventilation and control systems can become increasingly efficient without losing reliability or durability.

Frank Lock, Dipl.-Ing. (from 2002)

As the term “drive technology” no longer adequately reflected our broad range of services and technological diversity, Lock Antriebstechnik GmbH became Lock GmbH last year. By expanding our product range, we now offer a wide range of drive, positioning and automation solutions. As part of this process, three business units were founded: Lock Drives, Lock ProSystems and Lock SmartSolutions.

Start of series production of EWA 50. The year of digitalization. Introduction of BPM system. Start of series production of SBE Smart Farming.

Development of Lock's "Purpose". Great Place To Work employee survey. EFQM Assessment. Replacement of BI system and introduction of CPQ system. Excellent delivery reliability and delivery capability despite procurement crisis. Sales record EWA.

The LSC 40 smart controller goes into series production. Introduction of CRM system for sales and service. In the year of cooperation, Lock focuses on 5 top initiatives and successfully implements them despite the Corona pandemic. Procuration Jürgen Ammann. Lock Drives presence in Canada. Digital Christmas party.

Development of Lock brand core and booklet "Wir sind Lock". Great Place To Work employee survey and very successful EFQM assessment. 175 years of Lock with the highlights summer party with Johannes Warth and opening of the Lock Museum. 50th anniversary of the employee Berthold Fluhr. Frank Lock is appointed to the board of directors of KSK Biberach. Sales record with 99.5% delivery reliability.

Educational partnership with SRH Fernhochschule and Kreisgymnasium Riedlingen. Jeannette Lock is elected to the IHK General Assembly. Flexible production cell with pallet pool. Automated worm production.

In the "Year of Change" we pass vision, mission and medium-term strategy. New procedural organization. Foundation of the Chinese subsidiary Lock Drives Ltd. in Nanjing. New paint line with Power & Free System. EFQM Recognised for Excellence 4 Star. German Innovation Award BMEL for EZD 52.

Energy-Management-System in operation. Launch of position repeater PAR 10. Our product brochure is nominated for the INKA Award. The first LOLA-Fit Health Day is a great success. Market launch of EZD 51/52. Flexible production cell with pallet pool. Taspo Award "Most Innovative Product" for rack-and-pinion gear unit EZD 52.

Lock leadership principles and cultural rules are rolled out. Jeannette Lock is appointed 2nd Managing Director. Frank Lock becomes INDEGA President. Initiation of "Lean Assembly EWA". Taspo Award for best technical innovation: EazyVent® Duo. Delivery reliability and deliverability > 99%. Sales record and sales record EWA.

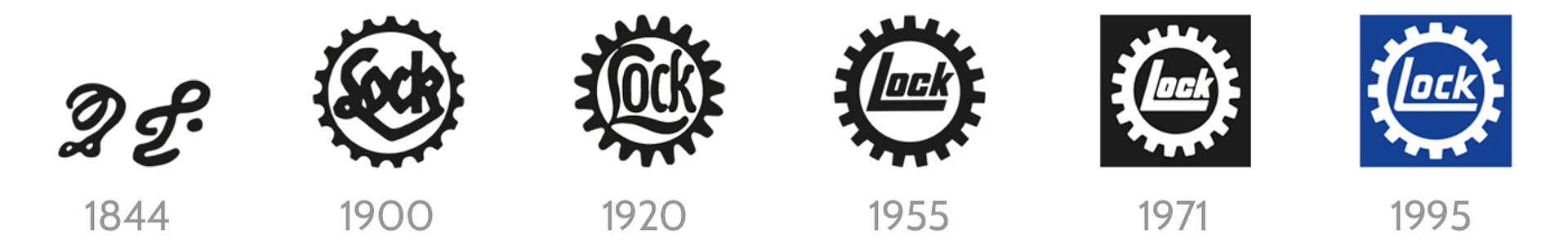

"170 years Lock. Thank you": Time travel at trade fairs and at the family party, more than 2000 visitors at the open day, 450 guests at the gala evening in the "Kulturhalle" with mental magician Andy Häussler. New gear milling machine. New corporate design. New catalogue. Lock values have been established.

The "year in flow" has been proclaimed. Introduction of the leadership system Leadership Energy SchmidtColleg and first implementation with "meeting culture". Start of the project "Lean Assembly EWA" with Staufen AG. The health management LOLA Fit shows first successes. Delivery reliability increases to 98%. Presentation of the rack and pinion jack EZW 64 at the Motek trade fair in Stuttgart.

Modernization and expanding offices and break rooms, slim layout production in main stock. New winding systemTF Diabolo, tube motor RMA 20 and frequency inverter “Speed Logic”. Profit record.

Move-in to new production hall; renaming Freimut-Lock-Strasse in honor of the company and the honorary citizen Freimut Lock; investment volume about 2.7 Mio. Euro; record quantity at the main product “EWA” and profit record; top rating

Start project “slim assembly” with assembly line “GKT”, first intern quality management-audit, start expansion of production hall; realization project “Welzel” – most modern and most complex convertible-ventilation system in worldwide greenhouse industry; 6.9.2010 ground breaking for the new production hall; profit-record.

Major project ThyssenKrupp headquarters in Essen (powertrain for primary façade with vertical closing sunscreen); birth of daughter Franka, Frank Lock finalist of Taspo Awards "Entrepreneur of the Year"; despite financial crisis: retiring of training master plan location Ertingen and construction completion of development road, 50 years electric drive

Large-scale project in Cologne Oval Office Cologne, founding of the subsidiary LOCK LOCK DRIVES INC. in Charlotte, NC, USA, Frank Lock Participation in control group "profession orientation" of Michel Buck School Ertingen; patent for motion control of shading / ventilation system

First participation at BAU exhibition in Munich; LanLogic bus system in series, 20% increase in sales, project Schüco Technology Center in Bielefeld

Senior Chief Freimut Lock dies; 70th Birthday senior director Ruth Lock and retirement; new drive Turbo Logic, 50-year employee anniversary Heinz Burgmeier, purchase of new lathes introducing new manufacturing system "3Liter-PPS", Frank Lock is elected to the Board of INDEGA

Introduction of a performance-based bonus system; patent for middle winding; major project Königsbau passages Stuttgart, introducing new ERP system INFOR COM

Award for new Indega VariVent system at fair IPM in Essen, 40 hour week and flexible work schedules; birth of daughter Montana

Establishment of subsidiary LOCK LOCK DRIVES BV in De Lier, Netherlands

Generational change to the fifth generation, leading corporate business director (100%) Frank Lock. Change of name to "Lock Antriebstechnik GmbH" and retirement of Freimut Lock, awarding the "INDEGA plaque for innovation in horticulture" for frequency inverter "FU plus LOGIC"

Freimut Lock, Dipl.-Ing. (FH) (1955 - 2001)

Awarded the Hortec-Plakette für technischen Fortschritt im Gartenbau" for wraparound blinds; member of NGMA "National Greenhouse Manufacturers Association" USA

Start of internet presence: www.lock.de; market launch of ZSG 12 ventilation rack and EWA 67 power drive; "Lock Drives USA" Service Center founded

Introduction of flexitime working for all employees; introduction of 3D CAD system; start of "Lock 2000+" strategy project and new corporate guidelines; market launch of EWA 12+14 power drives, LZG 17+18 ventilation drives; glass construction projects: Ministry of Justice, CDU Head Office in Berlin, mainline rail station in Frankfurt

New generation of saw and machining centre; introduction of bonus scheme for remuneration of hourly-paid staff; first trade fair attendance in the USA

First trade fair attendance, exhibiting at Eurotier in Hanover and IPM in Essen

Anniversary to celebrate 150 years of LOCK with an Open Day; founding member INDEGA

Company renamed to become "Lock Antriebstechnik Freimut Lock"

Expansion of production building and construction of a new office block on the Taubried industrial estate

Entry VDMA (German Engineering Federation)

IT for word processing, invoices, materials ordering, production control

Expansion of the production building on the Taubried industrial estate

New construction of factory building on the Taubried industrial estate

First automatic turning machine

Johannes Lock II, master fitter (1919-1955)

First major post-war investments, rack miling machine, hobbing machine

Construction of a new workshop building with office, Riedlingerstraße

Johannes Lock I, fitter (1884-1918)

Master craftsman business

Company entered in Trade Register

Another extension, this time an engine room for Deutz petrol engines driving a milling machine, a column-type drilling machine and a turning machine

Raphael Lock, fitter (1844-1884)

Extension to property in the form of a workshop building

Set up a workshop with forge in the basement of Riedlingerstr. 31 in Ertingen