Every greenhouse deserves an optimal climate. For this, there are horizontal screen systems based on proven drive principles such as wire screen and rack and pinion systems. Screen systems based on a rack and pinion system offer an effective solution for reducing the load on the front structure of your greenhouse and its sections. Compared to a cable screen, our rack and pinion system allows a reduction in Newton meters per motor. This helps to improve the efficiency of the structure.

Shade systems are installed as tight-fitting, hanging or overhead systems. The overhead shade system is placed directly on the greenhouse roof and provides a stable and robust structure. It is a fixed, horizontally mounted shade cover that filters sunlight and regulates the intensity of the sun's rays. The shade system is often less flexible in terms of adjusting the intensity of shading because it is usually a fixed structure. Adjustment is more likely to be done by selecting the level of shading when purchasing or by using manual covers. Due to its fixed structure, the overhead shade system can help reduce heat in the greenhouse by blocking some of the sunlight. However, it can also affect ventilation.

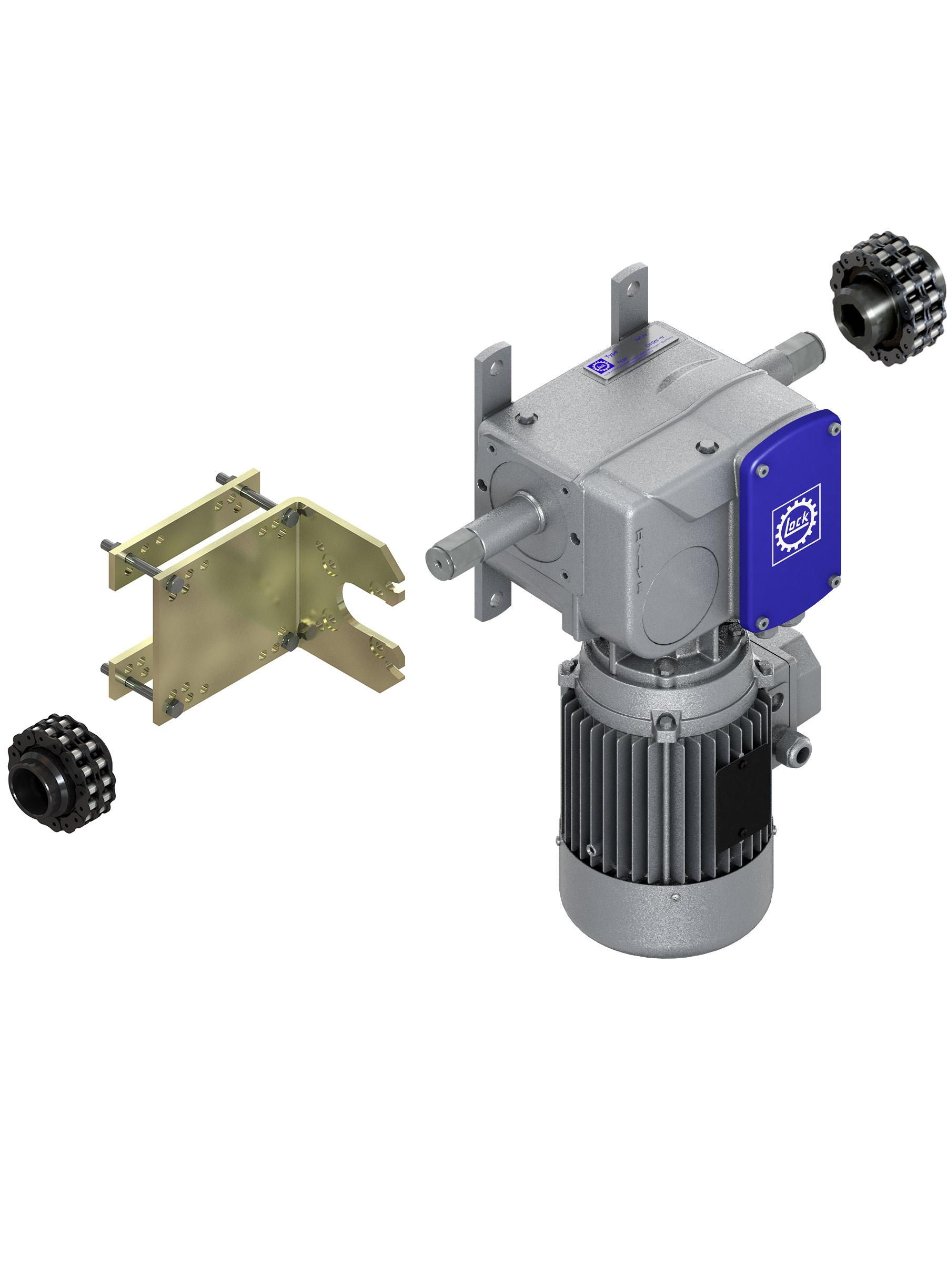

The EWA is mounted with a mounting plate clamped to the support. This creates an optimum installation position for setting the limit switch. Suitable for shading systems with fixed shading fabric, as well as systems with sliding blocks.

For horizontal and/or tent-shaped installations, a horizontal screen is installed in the upper part of the greenhouse. As most of a greenhouse's energy is lost through the greenhouse roof, an additional layer of insulation can be created with a horizontal and/or tent-shaped energy screen. By reducing heat radiation, this system immediately offers the greatest energy savings that can be achieved with screen installations in greenhouse construction.