Before building or modernizing your greenhouse, there are many important decisions to make

What size fits your operation? What crops do you want to grow – and what technology will you use for irrigation, ventilation or heating?

Alongside these practical considerations, you need to meet regulatory requirements, arrange financing, and find a reliable partner for implementation.

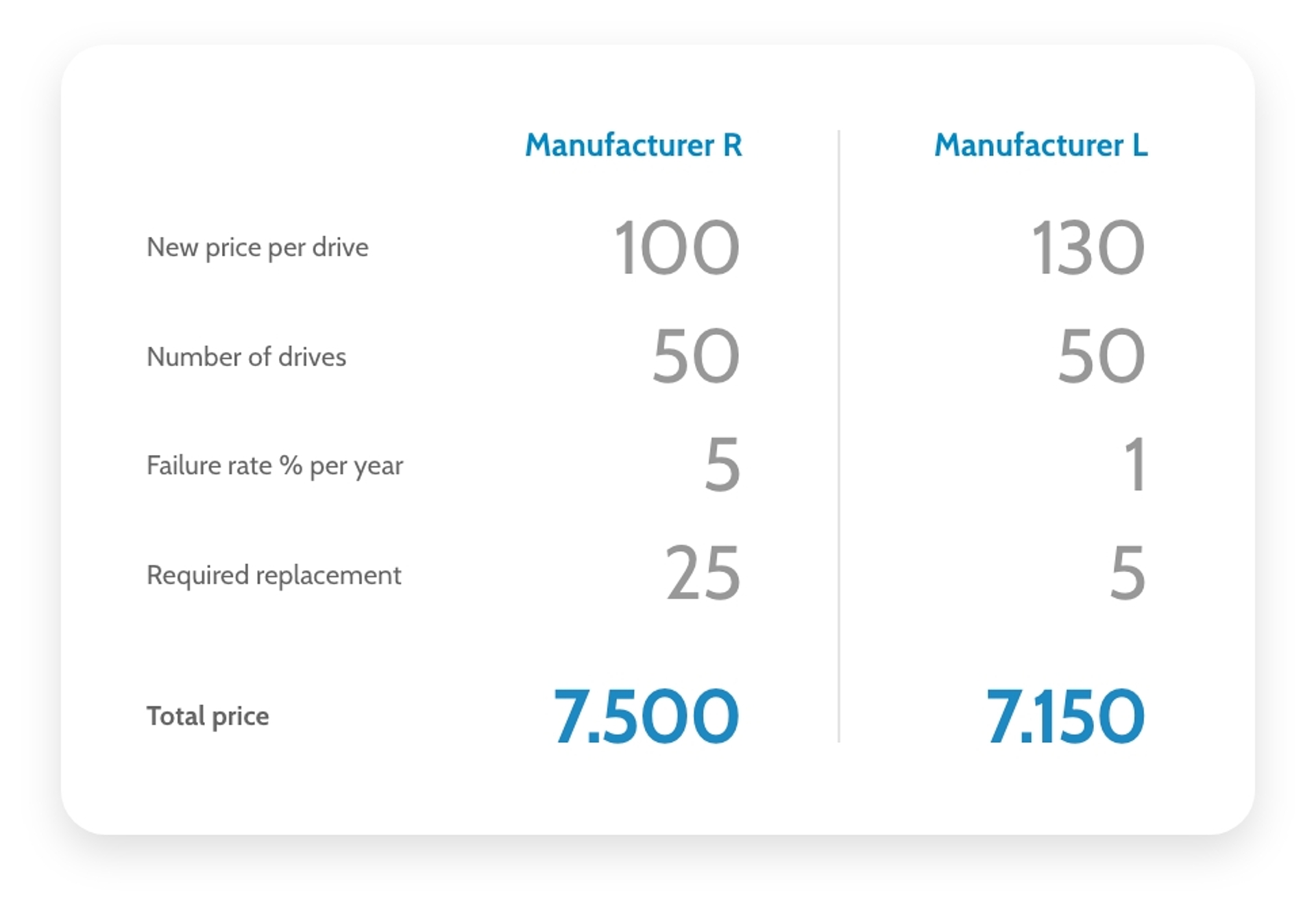

What your drive technology really costs – and how to save real money

At first glance, drive technology may seem like a minor part of your greenhouse budget. But over time, operating costs, repairs, maintenance and energy consumption add up – and that’s where hidden costs often lie.

Smart planning here leads to serious long-term savings. The cheapest drive isn’t always the most cost-effective – it’s the one that works reliably and efficiently for years.

Experts refer to this as the Total Cost of Ownership (TCO) – the total cost across a product’s entire lifetime. This includes:

- Purchase costs

- Energy consumption

- Maintenance and repairs

- Spare parts and disposal

We’ll show you how choosing the right drive technology can not only avoid headaches but also significantly reduce your long-term operating costs.

Your benefits with Lock as your partner

- Expert consulting: we support you as early as the planning phase, with free dimensioning or checking of existing layouts

- Quality made in Germany: with a complaint rate of just 1.77%, we’ve been a quality leader in drive technology for decades.

- Best overall cost performance (TCO): our technology stands out for durability and low operating costs – for maximum efficiency.

- More security: maintenance contracts and special warranty agreements, such as 10-year leak protection, complete our offering.

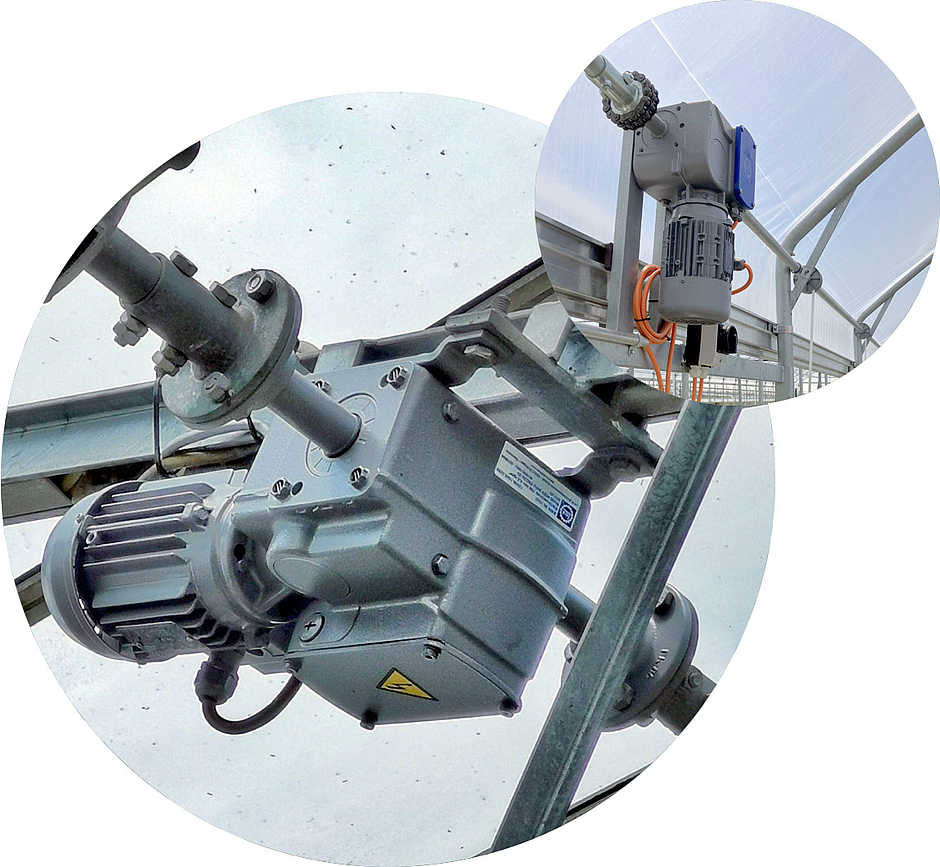

- Fast service: Lock motors can be replaced easily without draining the gearbox oil – saving time and effort.

Numbers that you should know

Key performance indicators (KPIs) are now indispensable management tools for companies and corporations.

0%

Customer Satisfaction

0%

Delivery Capability

0%

Delivery Loyality