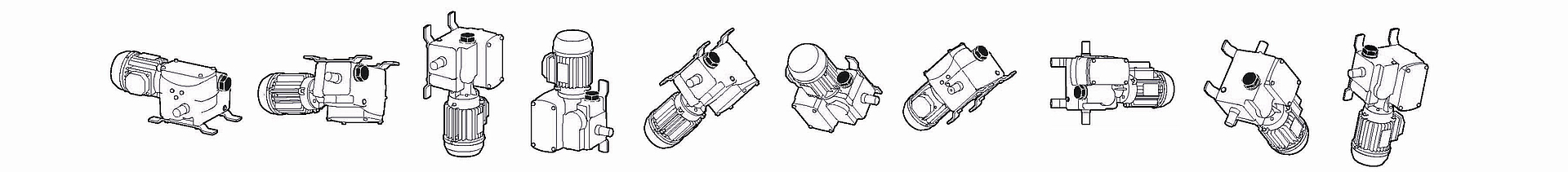

Lock power drives EWA

The EWA is the reliable power source for every application. Slow-running, with self-locking worm gear and integrated control unit, it performs its work for decades without any maintenance. It can be used for ventilation, shading, lifting and adjusting tasks in agricultural applications or in industry and is used in all sectors.

Numbers that you should know

Lock premium quality:

With a failure rate <1% over decades, the Lock EWA set standards in terms of quality and service life. Careful manufacturing with attention to detail, German engineering and an understanding of the application create a product that is second to none with satisfied customers worldwide. Long lasting Lock, our promise that we keep.

The development of new Lock drives always begins where they are to be used: in the application. The basic understanding of the application, the measurement of the physical conditions but also the assembly processes are the first steps and the basis. Added to this are decades of experience, the unique knowledge of Lock experts - whether in technology or production - and rigorous testing in our own test laboratory.

Only then does a new drive make it into series production. But that's not all: every drive produced is individually tested before it leaves the factory and is always subject to Lock's strict quality requirements.

Lock has been manufacturing self-locking gears since its foundation in 1844. This long experience guarantees a perfect combination of materials and maximum precision. A gearbox that never loses its self-locking ability and operates extremely quietly and smoothly. This is why EWA is suitable for industrial and agricultural applications as well as for areas with public traffic, such as DIY stores and garden centers.

The perfect combination of motor and gearbox generates the right torque for every application and ensures a long service life - even under dynamic full load.

A dynamic full load occurs when the application is subjected to additional short-term stress due to external influences. This can be caused by wind, snow, rain or mechanical problems in the drive train. By taking these cases into account, each EWA has a unique additional reserve that can further increase the service life and ensure greater safety in the application.

Use in all installation positions and in different locations is already taken into account in the design. Depending on the installation position, the required screw in the gearbox can become a ventilation screw with 2 turns. The EWA is designed so that the gear oil can expand without any problems, even at high temperatures. It also enables flexible and individual installation.

All gearbox housings consist of a one-piece cast housing and are made of gray cast iron. Grey cast iron is characterized by high strength and durability. Lock applications demand robustness and resilience over decades. Gray cast iron can withstand these high impact and load requirements and therefore guarantees a long service life. Compared to aluminum, the cast iron of Lock's EWA has superior thermal expansion. This is an advantage in warmer regions of the world to prevent oil leaks for a long service life. Due to the one-piece cast housing, oil leakage is not possible.

Each EWA is sealed at both shaft ends. This permanently prevents oil from escaping from the gearbox housing and also protects the compartment for the LSC or END control unit.

All EWAs are given a protective coating over the entire drive. This includes the motor, gearbox and shaft ends. All-round protection against impact, heat, moisture and dirt. In addition, all shafts undergo a special deep treatment, which results in the same properties as A2 stainless steel: Rust doesn't stand a chance. Furthermore, all motors are additionally protected by a tropicalized coating.

Single-phase EWA are always pre-wired and have overheating protection. This prevents wiring errors on site and prevents the motor from burning out.